Contactors and relays are valuable control devices. Both are commonly found in industries and businesses. They switch electrical loads on and off. While they have similarities, these devices differ in important ways. Choosing the right device is very crucial. Understanding the contactor vs relay differences ensures selecting the appropriate option for safety and performance.

Overview of Contactors

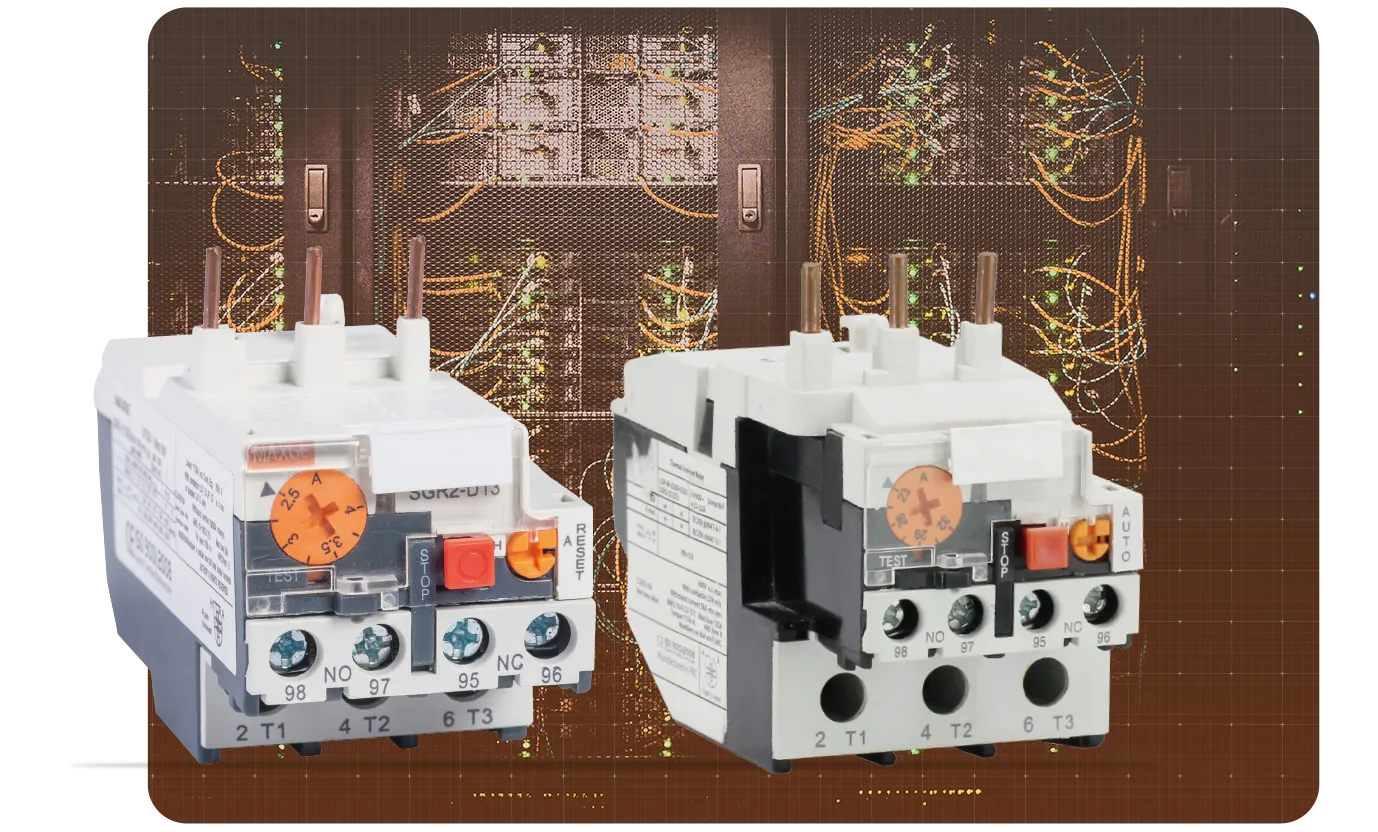

A contactor (such as an AC contactor) is an electrically controlled switching device. It switches on and off electrical loads. These include motors, lights, and heating elements. It features movable contacts that open and close under the command of an electromagnet. Contactors can handle high current loads. They feature robust construction, suited for single-phase and three-phase loads.

Contactors use an operating coil. When energized by a control signal, the coil generates a magnetic field to attract an armature. The attraction causes the contacts to change state. It’s either opening or closing. This occurs to pass current through or cut off the load circuit. Auxiliary contacts are also commonly seen on contactors. They provide signaling of contact position or control auxiliary circuits and devices.

Overview of Relays

A relay is also an electrically operated switching device. It’s primarily used for lower current switching applications compared to contactors. It typically features a set of fixed contacts and a movable set. These are operated by an electromagnet to complete or break an external circuit.

Relays are most commonly used for signaling, interlocking, and low-level control applications. The coil of a relay is energized by a low-power signal. It activates the normally open and normally closed contacts to pass or interrupt circuit power to a load.

Key Differences Between Contactors and Relays

The main contactor vs relay differences stem from their design purposes and rated loads:

- Rated Load

Contactors are engineered and constructed to easily manage high electric loads. They can handle currents up to 12500A amps (NOT SURE !!!!). On the other hand, relays are suited for controlling low to medium loads. It’s usually 10 amps or less due to their miniscule design.

- Size

Size is a major contactor vs relay difference. Contactors feature bulky, robust builds. These, with beefier components, enable them to channel high currents efficiently. Relays have more compact housings befitting their control of lower amperage.

- Structure

Contactors generally feature auxiliary contacts. They provide flexible switching options in addition to basic on/off functions. These contacts offer enhanced functions like status signaling. Relays solely open or close circuits through dedicated terminals.

- Phase

This aspect highlights the key contactor vs relay difference. Contactors prove valuable for single-phase job site equipment. They are also suitable for three-phase machinery. Relays get applied mainly to single-phase situations because of constrained size hindering multiphase switching capability.

- Cost

Since contactors require thick conductors, oversized coils, and rugged enclosures for safety, they involve pricier manufacturing. Relays escape such expenses through scaled-down, focused layouts.

Proper Selection Requires Several Considerations

The Contactor vs relay selection depends on several factors. These include the type and rating of the load being switched, expected duty cycle, ambient conditions, switching frequency, as well as installation and safety requirements. Other criteria include anticipated lifespan, connectivity options, enclosure type, diagnostics/feedback needed, and manufacturer specifications. Proper selection requires evaluation of these requirements against device capabilities.

Conclusion

Contactors and relays are both valuable control devices for switching electrical loads on and off. However, they have key distinctions in their design and application scope. Contactors are best suited for high current loads in industrial control and motor circuits. Relays excel for signaling and low-level switching in control logic. For reliable load control solutions, the reputed brand Maxge offers a comprehensive range of contactors and relays to suit any application.

At Maxge, we focus on quality and innovation. We have years of industry experience. We have a strong reputation as a relay manufacturer for our reliable, advanced products. Our rigorous production processes are certified to international standards. Browse our full catalog of contactors, relays, and other control components on our website https://www.maxge.com/ (i think you can also consider incorporating a hyperlink of our company website.)